Elasticity and Plasticity in Physics

Definition & Explanation

Elasticity and plasticity are two concepts in physics that describe how materials deform and respond to applied forces.

Elasticity refers to the ability of a material to deform under an applied force and then return to its original shape when the force is removed. Elastic materials can be stretched or compressed to a certain extent without undergoing permanent deformation. Examples of elastic materials are quarts fiber, rubber, nylon, lycra, and silicone.

Plasticity, on the other hand, refers to the ability of a material to undergo permanent deformation without breaking. Plastic materials can be stretched or compressed beyond their yield point, resulting in a change in shape that is not reversible. Examples of plastic materials are clay, mud, and wax.

Both elasticity and plasticity are important concepts in materials science and physics. The study of these phenomena is critical to understanding the behavior of different types of materials and predicting how they will respond to various external conditions, such as temperature changes or mechanical loading.

Elastic vs Plastic Deformation

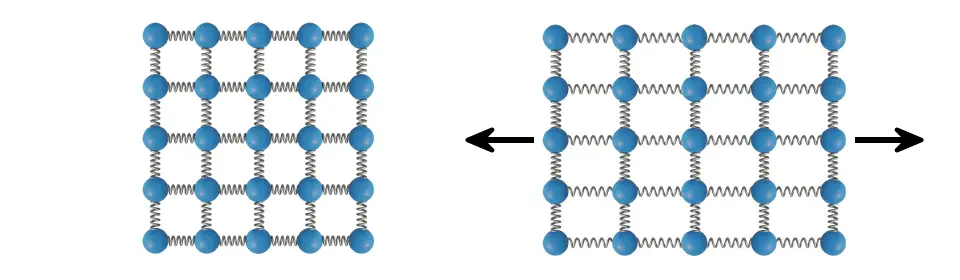

Elastic and plastic deformation are two types of deformation that a material can undergo when subjected to an external force.

Elastic deformation occurs due to the stretching or compression of the material’s atomic bonds, which can be modeled as springs that store and release energy as they are deformed and relaxed. The amount of deformation that occurs is proportional to the applied force, as described by Hooke’s law, which states that the stress (force per unit area) is proportional to the strain (deformation per unit length) for elastic materials.

The elasticity of a material is mainly determined by its different elastic moduli, such as young’s modulus, shear modulus, and bulk modulus, which measure the material’s resistance to elastic deformation. Materials with higher elastic moduli are more resistant to deformation and require larger forces to induce the same amount of deformation compared to materials with lower elastic moduli.

Plastic deformation occurs when the material’s atomic bonds are broken and reformed in new configurations, leading to permanent changes in the material’s shape. This process involves the movement of dislocations, which are defects in the material’s crystal structure that allow the atoms to slide past each other more easily. Dislocations can move in response to an applied force, allowing the material to deform plastically.

The plastic behavior of a material is described by its yield strength, which is the point at which the material transitions from elastic to plastic deformation. Beyond this point, the material will continue to deform plastically until it ultimately fails. Understanding the plastic behavior of materials is important in many fields, including materials science, engineering, and biomechanics.

Elastic-Plastic Behavior

Elastic-plastic behavior refers to the behavior of materials that exhibit both elastic and plastic deformation when subjected to an external force. When a material is loaded, it will initially undergo elastic deformation, meaning that the material will deform proportionally to the applied force and return to its original shape when the force is removed. However, if the applied force is increased beyond a certain threshold, the material will begin to exhibit plastic deformation, resulting in permanent changes to the material’s shape.

The elastic-plastic behavior of a material is described by its stress-strain curve, which plots the material’s stress against its strain as it is loaded. The curve typically exhibits a linear region at low stresses, corresponding to elastic deformation, followed by a nonlinear region at higher stresses, corresponding to plastic deformation.

The point at which the material transitions from elastic to plastic deformation is known as the yield point or yield strength. Beyond this point, the material will continue to deform plastically until it ultimately fails. The amount of plastic deformation that a material can undergo before failure depends on its properties and the conditions under which it is being loaded.

Elastic-plastic behavior is commonly observed in ductile materials, such as metals, which can undergo large amounts of plastic deformation before failing. It is also important in the design of structures and components, as it affects the material’s ability to withstand loads and stresses. By understanding the elastic-plastic behavior of materials, engineers and designers can develop safer and more reliable structures and products.

Difference Between Elasticity and Plasticity | |

|---|---|

| Elasticity | Plasticity |

| The ability of a material to regain its original shape when the deforming force is removed | The ability of a material to be molded and deformed permanently when acted on by a force |

| Deformation is recoverable | Deformation is permanent |

| Obeys Hooke’s law | Does not obey Hooke’s law |

| Elastic deformation occurs before plastic deformation | Plastic deformation only occurs after elastic deformation |

| Elastic deformation is quite small | Plastic deformation is large |

| Example: Rubber | Example: Mud |

Frequently Asked Questions

- How is elasticity measured in physics?

- The elasticity of a material is quantified by the different elastic moduli, such as the young’s modulus, shear modulus, and bulk modulus, which measure the ratio between stress to strain. Each modulus measures the elasticity of a material when a certain type of load / force is applied to it, for example the young’s modulus measures the material’s elasticity when it’s under a tensile or compressive load.

- Can a material exhibit both elastic and plastic behavior?

- Yes, a material can exhibit both elastic and plastic behavior. In fact, many materials exhibit both types of behavior when subjected to an external force.

- Does temperature affect the elasticity of a material?

- Yes, elasticity is inversely proportional to temperature, which means as a material’s temperature increases, its elasticity decreases, and vice versa.